Manual wheelchair lifts are essential accessibility solutions designed to assist individuals with mobility challenges. They provide safe and efficient transfers, enabling independence and ease of movement. These lifts are cost-effective, portable, and suitable for various settings, offering a practical alternative to ramps or stairs.

1.1 Definition and Purpose

A manual wheelchair lift is a device designed to transfer individuals with mobility challenges safely and efficiently. It operates without electricity, relying on manual effort or hydraulic systems. The primary purpose of these lifts is to provide accessibility in various settings, such as homes, vehicles, or public spaces. They are ideal for temporary or portable use, offering a practical solution for overcoming physical barriers and ensuring independence for users. Their compact design and ease of operation make them a versatile tool for everyday accessibility needs.

1.2 Importance of Manual Wheelchair Lifts

Manual wheelchair lifts play a crucial role in enhancing accessibility for individuals with mobility challenges. They are cost-effective, easy to install, and versatile, making them ideal for various settings. These lifts ensure safe and efficient transfers, promoting independence and dignity for users. Their portability and reliability in emergency situations further highlight their importance. By bridging physical barriers, manual wheelchair lifts contribute significantly to creating inclusive environments and improving overall quality of life for those who rely on them.

Types of Manual Wheelchair Lifts

Manual wheelchair lifts are categorized into hydraulic and manual operation, as well as portable and installed models. Each type offers unique benefits and suitability.

2.1 Hydraulic vs. Manual Operation

Hydraulic wheelchair lifts rely on fluid pressure for smooth, controlled movements, offering precise height adjustment and reliability. Manual lifts, powered by hand cranks or levers, are cost-effective and portable, ideal for temporary use. Hydraulic systems provide easier operation with heavy loads, while manual lifts require physical effort but are lightweight and versatile. Both types ensure safe and efficient transfers, catering to different user needs based on preferences and accessibility requirements.

2.2 Portable vs. Installed Lifts

Portable manual wheelchair lifts are lightweight, foldable, and easy to transport, making them ideal for temporary or multiple-location use. Installed lifts, however, are permanently fixed, offering stability and durability for long-term accessibility solutions. Portable lifts are perfect for users who need flexibility, while installed lifts provide a reliable, fixed solution for homes, vehicles, or public spaces. Both options cater to different needs, ensuring accessibility in various settings.

Key Features of Manual Wheelchair Lifts

Manual wheelchair lifts feature durable construction, easy operation, and essential safety mechanisms. They offer adjustable platforms, weight capacity options, and portability for versatile use across different environments.

3.1 Weight Capacity and Platform Size

Manual wheelchair lifts are designed with varying weight capacities to accommodate different user needs, typically ranging from 300 to 750 pounds. The platform size is also customizable, ensuring it can support standard wheelchairs, power chairs, and scooters. Proper sizing and capacity are essential for safe operation, as exceeding limits can compromise safety and equipment longevity. Always refer to manufacturer guidelines to ensure the lift meets the specific requirements of the user. This ensures optimal performance and reliability.

3.2 Safety Mechanisms

Manual wheelchair lifts are equipped with essential safety mechanisms to ensure secure operation. Emergency stop systems and manual override features allow for immediate control in critical situations. Toe shear guards prevent foot injuries during movement, while handrails provide additional stability. Weight capacity limits are strictly enforced to prevent overload risks. Non-slip platforms and smooth transitions enhance user safety. Regular maintenance checks and adherence to manufacturer guidelines further ensure reliability and optimal performance, safeguarding both the user and the equipment.

3.3 Ease of Use

Manual wheelchair lifts are designed for straightforward operation, ensuring users can transfer safely and efficiently. Many models feature intuitive controls and lightweight designs, making them easy to maneuver without requiring extensive strength. Portable options allow for seamless relocation, while fixed installations provide consistent accessibility. Smooth transitions between levels and minimal training requirements further enhance usability, ensuring that both users and attendants can operate the lift with confidence and ease.

Benefits of Manual Wheelchair Lifts

Manual wheelchair lifts offer enhanced accessibility, affordability, and versatility, making them ideal for various settings. They provide cost-effective solutions for mobility challenges, promoting independence and ease of use.

4.1 Enhanced Accessibility

Manual wheelchair lifts significantly improve accessibility for individuals with mobility challenges. They enable safe and effortless navigation over stairs, into vehicles, or across raised platforms. These lifts are designed to accommodate various wheelchair types, ensuring smooth transitions and minimizing barriers. By providing reliable access to previously inaccessible areas, manual lifts promote independence and confidence for users in both private and public settings. Their portability and ease of installation further enhance their ability to adapt to different environments, making them a versatile accessibility solution.

4.2 Cost-Effectiveness

Manual wheelchair lifts are a budget-friendly option for enhancing mobility. They often require lower upfront costs compared to electric models and involve minimal installation expenses. With fewer mechanical components, maintenance and repair costs are reduced, ensuring long-term savings. Their durability and reliability make them a cost-effective solution for both temporary and permanent accessibility needs, offering value without compromising on safety or functionality. This makes them an ideal choice for individuals and businesses seeking affordable accessibility solutions.

4.3 Versatility in Different Settings

Manual wheelchair lifts are adaptable to various environments, making them suitable for homes, businesses, and public spaces. Their portability and ease of installation allow them to be used in stairways, porches, and even vehicles. They are ideal for both permanent and temporary accessibility needs, offering flexibility without requiring extensive renovations. This versatility ensures they can meet diverse mobility challenges across different settings, providing reliable access solutions wherever they are needed.

Installation of Manual Wheelchair Lifts

The installation of manual wheelchair lifts involves site preparation, step-by-step assembly, and post-installation checks to ensure proper functionality and safety, adhering to manufacturer guidelines.

5.1 Site Preparation

Proper site preparation is crucial for the installation of manual wheelchair lifts. This includes assessing the area to ensure it is level, structurally sound, and free from obstructions. The site must be cleared of debris, and any uneven surfaces should be leveled. Additionally, ensuring adequate space for the lift and its components is essential. It is important to follow manufacturer guidelines to guarantee a safe and stable installation environment, preventing potential issues during and after the setup process.

5.2 Step-by-Step Installation Process

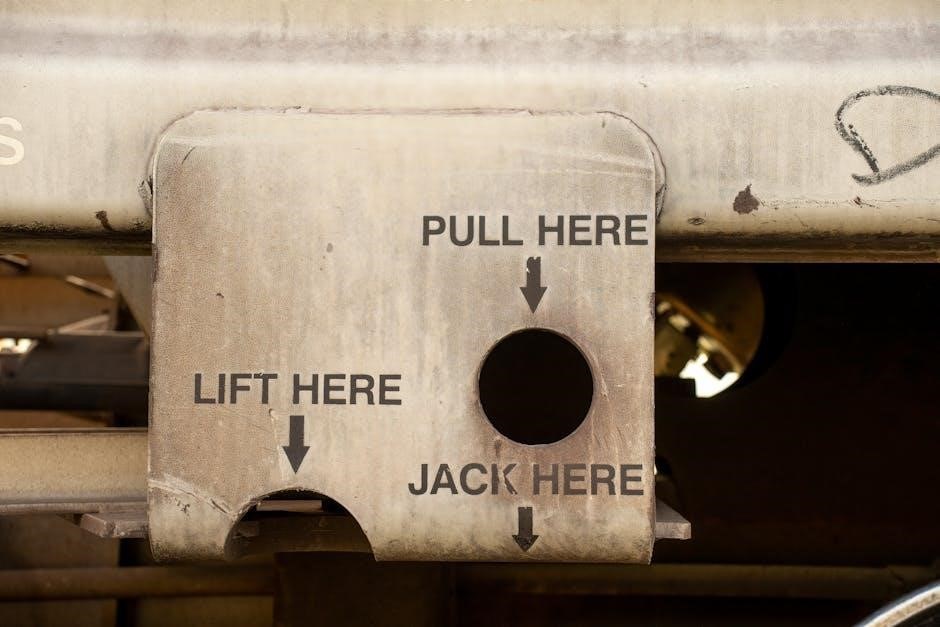

The installation of a manual wheelchair lift involves a systematic approach to ensure safety and functionality. Begin by unpacking and inspecting all components for damage. Anchor the base to the floor or a concrete slab, ensuring stability. Attach the mast and platform according to manufacturer instructions, followed by the installation of safety features like toe guards and handrails. Finally, test the lift under load to ensure smooth operation and make any necessary adjustments to guarantee proper performance and user safety.

5.3 Post-Installation Checks

After installing a manual wheelchair lift, perform thorough post-installation checks to ensure optimal functionality and safety. Verify that all bolts and screws are securely tightened and that the lift operates smoothly under load. Test the safety mechanisms, such as emergency stops and platform locks, to ensure they function correctly. Inspect the platform for levelness and the surrounding area for any obstructions. Conduct a final test with the maximum weight capacity to confirm reliability and make any necessary adjustments before granting user access.

5.4 Common Installation Mistakes to Avoid

To ensure a safe and functional manual wheelchair lift installation, avoid common mistakes such as improper site preparation, incorrect bolt torque, and misaligned platform assembly. Skipping steps in the installation manual or failing to test the lift under full weight capacity can lead to safety hazards. Additionally, avoid using unapproved materials or neglecting to secure the lift properly to the floor or wall. Always follow manufacturer guidelines to prevent operational issues and ensure compliance with safety standards. Proper installation is critical for reliability and user safety.

Safety Considerations

Safety is paramount when using manual wheelchair lifts. Always adhere to load capacity guidelines, ensure proper usage, and conduct regular maintenance checks to prevent accidents.

6.1 Safety Features

Manual wheelchair lifts are equipped with essential safety features to ensure secure operation. These include non-slip platforms, safety belts, and emergency stop mechanisms.

- Load capacity sensors prevent overloading.

- Emergency manual lowering systems are available.

- Visual and auditory alerts signal operation status.

- Platform barriers and toe guards prevent accidents.

These features ensure user safety and compliance with accessibility standards, providing peace of mind for both users and caregivers. Regular inspections are crucial to maintain reliability.

6.2 Proper Usage Guidelines

Proper usage of manual wheelchair lifts ensures safe and efficient operation. Always follow the manufacturer’s instructions and guidelines.

- Ensure the lift is installed and maintained correctly.

- Prepare the site by clearing obstacles and ensuring a firm, level surface.

- Adhere to the maximum load capacity to prevent overloading.

- Trained attendants should assist users during loading and unloading.

- Secure the wheelchair and user properly before lifting.

- Avoid operating the lift in extreme weather conditions unless specified as safe.

Proper usage extends the lifespan of the lift and ensures user safety.

6.3 Maintenance Tips

Regular maintenance is crucial to ensure the longevity and safety of manual wheelchair lifts.

- Lubricate moving parts periodically to reduce friction and wear.

- Inspect cables, pulleys, and hinges for signs of wear or damage.

- Check safety mechanisms, such as emergency stops and brakes, to ensure proper function.

- Store the lift in a dry, secure location when not in use.

- Follow the manufacturer’s maintenance schedule and guidelines.

Proper upkeep ensures reliable operation and user safety.

6.4 Emergency Procedures

In case of an emergency, remain calm and follow these steps:

- Activate the emergency stop or manual release mechanism to stabilize the lift.

- Ensure the platform is secure and clear of obstacles.

- Avoid exceeding weight capacity during manual operation.

- Contact a trained technician or emergency services for assistance.

Proper emergency protocols ensure safety and quick resolution.

Best Practices for Using Manual Wheelchair Lifts

Always follow manufacturer guidelines, perform regular maintenance, and train attendants to ensure safe and efficient operation of manual wheelchair lifts.

7.1 Load and Unload Procedures

Proper loading and unloading are crucial for safe operation. Ensure the lift is on a level surface and the platform is clear of obstructions. Position the wheelchair correctly, secure it with safety straps, and maintain balance. Always follow the manufacturer’s guidelines for weight capacity and ensure the user is centered on the platform. Use handrails if available and avoid sudden movements. Practice these steps to build confidence and ensure smooth transitions.

7.2 Regular Maintenance

Regular maintenance ensures optimal functionality and safety of manual wheelchair lifts. Check for wear and tear on moving parts, lubricate hinges and joints, and verify safety mechanisms like emergency stops. Inspect cables and pulleys for damage and ensure all bolts are securely tightened. Refer to the user manual for specific maintenance schedules and guidelines. Address any issues promptly to prevent breakdowns and extend the lift’s lifespan, ensuring reliable performance and user safety. Schedule professional inspections annually for comprehensive evaluation.

7.3 Training for Attendants

Proper training for attendants is crucial to ensure safe and effective use of manual wheelchair lifts. Training should cover operation procedures, safety mechanisms, and emergency protocols. Attendants must understand how to securely position the wheelchair, operate controls, and handle unexpected situations. Practical exercises and regular refreshers are essential to maintain proficiency. Adhering to manufacturer guidelines ensures compliance and maximizes user safety, making attendants confident and competent in lift operation. This training fosters independence for users while minimizing risks.

Manual wheelchair lifts offer unique advantages over ramps, stairlifts, and electric lifts. They are cost-effective, portable, and require minimal installation, making them ideal for various settings and needs. Manual wheelchair lifts differ significantly from electric models, primarily in operation and cost. Electric lifts use motorized systems for effortless height adjustment, offering greater convenience for frequent use. In contrast, manual lifts rely on physical effort or hydraulic systems, making them more affordable and suitable for occasional use. While electric lifts provide faster operation, manual lifts are preferred for their portability and lower maintenance requirements. Each option caters to different user needs and budgets. Manual wheelchair lifts offer a space-saving alternative to ramps, which require significant floor space and construction. Unlike ramps, lifts provide vertical mobility without altering the surrounding area, making them ideal for tight spaces. While ramps are often more affordable upfront, lifts require less maintenance and can be more durable long-term; Additionally, lifts ensure smoother transitions between levels, reducing effort for users. This makes manual lifts a practical choice for accessibility in both residential and commercial settings. Manual wheelchair lifts are more versatile and space-efficient compared to stairlifts. While stairlifts are designed for navigating stairs, manual lifts provide vertical accessibility without requiring extensive installation or a dedicated rail system. They are ideal for tight spaces and temporary use, whereas stairlifts are often permanent fixtures. Additionally, manual lifts are more cost-effective and easier to maintain, making them a practical choice for users seeking flexibility and convenience in mobility solutions. They also offer a wider range of applications beyond stair navigation. Manual wheelchair lifts must comply with accessibility codes and manufacturer guidelines to ensure safety and proper functionality. Adherence to these standards is crucial for legal and operational requirements. Manual wheelchair lifts must comply with accessibility codes, such as those outlined by the ADA, ensuring safe and equitable access for all users. These codes specify requirements for platform size, weight capacity, and safety features. Compliance guarantees that lifts meet legal standards and provide reliable service. Manufacturers often provide guidelines to help installers adhere to these regulations, ensuring proper installation and operation. Adherence to accessibility codes is essential for protecting users and avoiding legal issues. Manufacturer guidelines for manual wheelchair lifts provide detailed instructions for installation, maintenance, and operation. These guidelines ensure compliance with safety standards and optimal performance. Proper adherence to manufacturer instructions is crucial for warranty validity and user safety. They often include specific steps for site preparation, installation processes, and post-installation checks. Ignoring these guidelines can lead to safety hazards or equipment malfunction, emphasizing the importance of following them closely to ensure reliable and efficient lift operation. Users praise manual wheelchair lifts for their reliability, ease of use, and durability. Many highlight how these lifts have improved accessibility and independence in daily life. Customers frequently highlight the ease of installation and operation of manual wheelchair lifts. Many users appreciate their portability and versatility, making them suitable for both home and public settings. The lifts have received positive feedback for their durability and reliability, with several customers noting how they have significantly enhanced their accessibility and independence. Overall, manual wheelchair lifts are widely regarded as a practical and effective solution for mobility challenges. Manual wheelchair lifts consistently receive high satisfaction ratings for their ease of use and reliability. Users often praise their durability and cost-effectiveness, making them a valuable investment for long-term accessibility needs. Many customers highlight the lifts’ ability to seamlessly integrate into various settings, enhancing overall mobility without compromising space or aesthetics. Satisfaction levels remain strong, with users appreciating the lifts’ performance and the independence they provide. These ratings underscore the lifts’ reputation as a practical and efficient accessibility solution. Common issues with manual wheelchair lifts include mechanical failures, operational problems, and maintenance-related concerns. Regular checks and proper maintenance can help prevent or resolve these issues promptly. Mechanical failures in manual wheelchair lifts often stem from worn or damaged components, such as hydraulic cylinders, pulleys, or cables. Regular lubrication of moving parts and inspection of wire ropes can prevent breakdowns. If a lift malfunctions, stop use immediately and contact a certified technician. Always refer to the manufacturer’s manual for diagnostic guidance and ensure replacement parts meet safety standards. Proper maintenance and timely repairs are crucial to avoiding accidents and extending the lift’s lifespan. Operational problems with manual wheelchair lifts often arise from improper installation, lack of maintenance, or user error. Issues like uneven platform alignment, jerky movements, or failure to lock in place can disrupt smooth operation. Regular lubrication of mechanical parts and adherence to weight limits are crucial. Users should also ensure proper handrail installation and follow safety guidelines to prevent accidents. Addressing these issues promptly through routine inspections and user training can minimize downtime and ensure reliable performance. Regular maintenance is crucial to ensure the longevity and functionality of manual wheelchair lifts. Common concerns include wear and tear on moving parts, corrosion, and improper lubrication. Users should inspect bolts, hinges, and cables for tightness and damage. Lubricating pivot points and ensuring proper alignment can prevent operational issues. Additionally, adhering to manufacturer guidelines for servicing and addressing any wear on platforms or handrails is essential to maintain safety and efficiency. Proper upkeep prevents costly repairs and downtime. Manual wheelchair lifts are vital tools for enhancing mobility and independence. Their cost-effectiveness, portability, and ease of use make them a practical solution for various accessibility needs. Manual wheelchair lifts are a practical and essential solution for improving accessibility and independence. Their cost-effectiveness, portability, and ease of use make them a versatile option for various settings. Whether installed permanently or used as a portable solution, these lifts provide reliable assistance for individuals with mobility challenges. By addressing accessibility needs efficiently, manual wheelchair lifts continue to be a valuable tool in promoting inclusivity and enhancing quality of life for many users. The future of manual wheelchair lifts is promising, with advancements in design and technology expected to enhance functionality and accessibility. Innovations such as lightweight materials, improved safety features, and integrated assistive technologies will likely dominate the market. Additionally, there may be a shift toward more eco-friendly and energy-efficient solutions. As accessibility needs evolve, manual wheelchair lifts will continue to play a crucial role in providing reliable and adaptable mobility solutions for users worldwide.

Comparison with Other Accessibility Solutions

8.1 Vs. Electric Wheelchair Lifts

8.2 Vs. Ramps

8.3 Vs. Stairlifts

Regulations and Compliance

9.1 Accessibility Codes

9.2 Manufacturer Guidelines

User Reviews and Testimonials

10.1 Customer Experiences

10.2 Satisfaction Ratings

Troubleshooting Common Issues

11.1 Mechanical Failures

11.2 Operational Problems

11.3 Maintenance-Related Concerns

12.1 Final Thoughts

12.2 Future of Manual Wheelchair Lifts