The Porter-Cable FN250SB is a heavy-duty pneumatic finish nailer designed for 16-gauge finish nails‚ ideal for woodworking and construction projects. This manual provides essential guidance for safe operation‚ maintenance‚ and troubleshooting to ensure optimal performance and longevity of the tool.

1.1 Overview of the Tool

The Porter-Cable FN250SB is a 16-gauge pneumatic finish nailer designed for high-speed‚ high-volume nailing tasks. It is ideal for professional contractors and DIYers alike‚ offering precision and durability. The tool features a robust design with an integrated belt hook for convenience. It supports 16-gauge finish nails ranging in length from 1″ to 2-1/2″‚ making it versatile for various woodworking and construction projects. The FN250SB is known for its reliable performance‚ ergonomic design‚ and ease of use‚ making it a popular choice for finishing applications such as trim work‚ cabinetry‚ and furniture assembly.

1.2 Importance of the Manual

The Porter-Cable FN250SB manual is essential for ensuring safe and effective use of the tool. It provides detailed instructions on assembly‚ operation‚ and maintenance‚ helping users maximize performance and prevent damage. The manual includes safety precautions‚ troubleshooting tips‚ and warranty information‚ which are crucial for maintaining the tool’s longevity. By following the guidelines outlined in the manual‚ users can avoid potential hazards and ensure optimal functionality. Regularly reviewing the manual helps users stay informed about best practices and proper care‚ making it a vital resource for both novice and experienced operators.

Safety Precautions and Guidelines

Always follow safety guidelines to prevent accidents. Use approved Porter-Cable nails‚ avoid modifying the tool‚ and handle it with care. Proper usage ensures safety and tool longevity.

2.1 General Safety Instructions

Always read and follow the safety guidelines in this manual to ensure safe operation. Wear protective gear‚ including safety glasses and gloves‚ when using the tool. Keep loose clothing and long hair tied back to avoid entanglement. Ensure the work area is well-lit and free from clutter. Never modify the tool or use it for purposes other than its intended design; Keep children and bystanders away while operating the nailer. Avoid using the tool when fatigued or under the influence of drugs or alcohol. Proper handling and adherence to these precautions will minimize risks and ensure a safe working environment.

2.2 Handling and Storage Tips

Handle the Porter-Cable FN250SB with care to prevent damage and ensure longevity. Store the tool in a dry‚ clean environment‚ away from direct sunlight and moisture. Use a protective case or bag to safeguard the nailer during transport or storage. Regularly inspect the tool for wear or damage‚ addressing issues promptly to maintain performance. Keep the nailer out of reach of children and unauthorized users. Avoid exposing the tool to extreme temperatures or vibrations. Clean the nailer after use‚ removing dirt and debris to prevent corrosion. Proper handling and storage will help preserve the tool’s functionality and ensure safe operation over time.

Key Features and Specifications

The Porter-Cable FN250SB is a 16-gauge pneumatic finish nailer‚ compatible with 1″ to 2-1/2″ nails. It features a durable design‚ efficient magazine system‚ and robust build quality for reliable performance.

3.1 Design and Build Quality

The Porter-Cable FN250SB boasts a robust and durable design‚ ensuring long-lasting performance. Constructed with high-quality materials‚ it features an ergonomic grip for comfortable handling and reduced fatigue during extended use. The tool’s compact and lightweight design enhances portability‚ making it ideal for various woodworking and construction tasks. Its rugged build withstands the demands of heavy-duty projects while maintaining precision and consistency; Safety and efficiency are prioritized through its intuitive layout and secure components‚ ensuring reliable operation and minimizing downtime. This finish nailer is built to deliver professional-grade results in high-speed‚ high-volume nailing applications.

3.2 Compatible Nail Sizes and Types

The Porter-Cable FN250SB is designed to work with 16-gauge finish nails‚ ranging in length from 1 inch to 2.5 inches. It accepts both 16-gauge straight and angled finish nails‚ ensuring versatility for various woodworking and construction projects. For optimal performance‚ it is recommended to use Porter-Cable approved finish nails‚ as specified in the manual‚ to maintain safety and functionality. Using unapproved nails may compromise tool performance and safety. The tool’s compatibility with a wide range of nail sizes and types makes it suitable for both light-duty and heavy-duty applications‚ providing flexibility for different user needs and project requirements.

3.3 Magazine System and Loading Mechanism

The Porter-Cable FN250SB features a convenient “load and lock” magazine system‚ allowing for quick and easy reloading of nails. The magazine is designed to hold a generous quantity of 16-gauge finish nails‚ minimizing downtime during projects. To load‚ simply flip open the magazine‚ insert the nails‚ and lock it back into place. The tool is equipped with a visual indicator to show when nails are running low. Proper alignment and secure locking of the magazine are crucial for consistent performance. Always ensure the magazine is fully closed and latched before operating the tool to avoid jams or misfires.

Operating Instructions

Follow proper techniques for firing nails‚ ensuring safety and precision. Always maintain control and align nails correctly for consistent results. Refer to the manual for detailed guidance.

4.1 Assembly and Initial Setup

Begin by carefully unboxing and inspecting the Porter-Cable FN250SB for any damage. Attach the integrated belt hook for convenient storage. Familiarize yourself with the tool’s components‚ such as the trigger and magazine. Ensure all parts are securely in place before use. Follow the manual’s guidance for proper assembly‚ including the installation of any additional accessories; Always use genuine Porter-Cable parts to maintain performance and safety. Once assembled‚ test the nailer with a few practice nails to ensure it functions correctly. Proper setup ensures efficient and precise nailing‚ adhering to the tool’s specifications and safety standards.

4.2 Loading Nails and Accessories

Before loading nails‚ ensure the tool is turned off and the trigger is locked to prevent accidental firing. Open the magazine by releasing the latch and pivoting it open. Insert the 16-gauge finish nails into the magazine‚ ensuring they align correctly with the guide. Do not overfill the magazine‚ as this can cause jamming. Close the magazine securely and test the nailer by firing a few nails into scrap material to ensure proper function. Always use Porter-Cable-approved nails and accessories to maintain performance and safety. Proper loading ensures efficient and reliable operation of the FN250SB finish nailer.

4.3 Firing and Operation Techniques

Hold the Porter-Cable FN250SB firmly with both hands‚ maintaining control during operation. Position the nailer at the desired angle‚ ensuring the tip is flush with the work surface. Squeeze the trigger gently but firmly to fire a nail. Always keep your fingers away from the muzzle to avoid injury. For sequential firing‚ move the nailer to the next position and repeat. Use consistent‚ steady pressure to maintain accuracy. After firing‚ inspect the workpiece to ensure proper nail placement. Regularly check the nailer’s alignment and adjust as needed to prevent misfires or uneven nail setting.

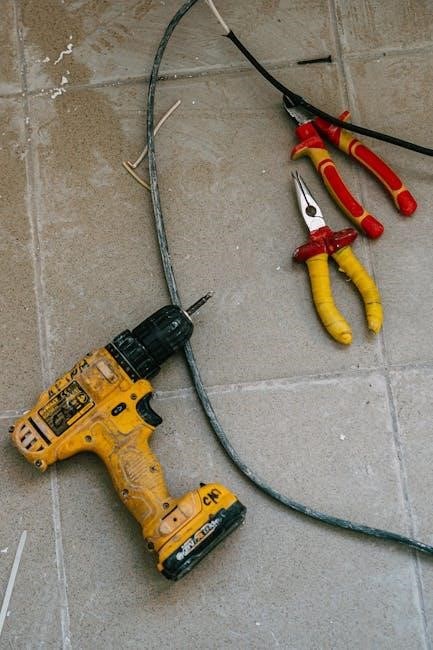

Maintenance and Care

Regularly clean and lubricate the Porter-Cable FN250SB to ensure smooth operation and prevent rust. Store it in a dry place and check for worn parts to maintain performance.

5.1 Regular Cleaning and Lubrication

Regular cleaning and lubrication are essential for maintaining the Porter-Cable FN250SB’s performance and longevity. Use a soft cloth to wipe down the tool‚ removing dirt and debris from the exterior and internal components. Apply a few drops of Porter-Cable-approved lubricant to moving parts‚ such as the piston and trigger mechanism‚ to ensure smooth operation. Clean the magazine and nail exit area to prevent jams. Inspect for worn or damaged parts and replace them as needed. Avoid using harsh chemicals or excessive lubrication‚ as this can damage the tool. Always follow the manual’s recommendations for lubrication frequency and techniques.

5.2 Troubleshooting Common Issues

Common issues with the Porter-Cable FN250SB include nails not feeding properly‚ jamming‚ or the tool not firing. If nails aren’t feeding‚ check the magazine alignment and ensure it’s fully locked. For jams‚ turn off the tool‚ release the pressure‚ and carefully remove the jammed nail. If the tool doesn’t fire‚ ensure the air pressure is within the recommended range and the trigger is functioning correctly. Clean the tool regularly to prevent dirt buildup‚ which can cause malfunctions. Refer to the manual for detailed troubleshooting steps and solutions to restore optimal performance and extend the tool’s lifespan.

Additional Resources and Support

Access additional resources‚ including manuals and troubleshooting guides‚ on the Porter-Cable website. Utilize ServiceNet for online manuals and contact customer support for further assistance.

6.1 Downloading the Manual

To download the Porter-Cable FN250SB manual‚ visit the official Porter-Cable website. Navigate to the “Service & Support” section and use the model number search tool. Enter “FN250SB” in the search field to locate the manual. Select the desired document and click the download button to access the PDF version. This manual contains detailed instructions for operation‚ maintenance‚ and troubleshooting. Ensure you review it thoroughly for safe and effective use of your finish nailer. Additionally‚ the manual is available in multiple languages‚ catering to a diverse user base.

6.2 Customer Service and Warranty Information

Porter-Cable offers comprehensive customer support for the FN250SB. For inquiries‚ contact their customer service team via phone or email through the official website. The tool is backed by a warranty program‚ with details provided in the manual. Visit the Porter-Cable website or refer to the “Service & Support” section for warranty terms and conditions. Additionally‚ authorized service centers are available for repairs and maintenance‚ ensuring your tool remains in optimal condition. For further assistance‚ utilize the SERVICENET platform‚ which provides access to resources and support tailored to your needs.

The Porter-Cable FN250SB is a reliable tool for efficient nailing tasks. Proper usage and maintenance ensure optimal performance. Refer to the manual for detailed guidance and support.

7.1 Final Tips for Optimal Use

For optimal performance‚ always use approved Porter-Cable nails and maintain proper tool lubrication. Regularly clean the nailer and store it safely. Adhere to safety guidelines to prevent accidents and ensure longevity. Follow the manual’s instructions for loading and firing to achieve professional results. Proper handling and storage prevent damage. Use the integrated belt hook for convenience on job sites. Refer to troubleshooting tips in the manual for common issues. By following these guidelines‚ you’ll maximize efficiency and extend the tool’s lifespan. Always prioritize safety and proper maintenance for consistent‚ reliable performance.

7.2 Importance of Following Manual Guidelines

Adhering to the Porter-Cable FN250SB manual ensures safe and efficient operation‚ preventing accidents and tool damage. Proper use extends the tool’s lifespan and maintains warranty validity. Following guidelines helps avoid misuse‚ ensuring consistent performance and professional results. Safety precautions‚ loading instructions‚ and maintenance tips are crucial for optimal functionality. Ignoring manual recommendations can lead to malfunctions or injuries. Always refer to the manual for troubleshooting and maintenance procedures. By following the provided instructions‚ users can maximize the tool’s potential and ensure reliable performance. Compliance with manual guidelines is essential for both user safety and tool longevity.